CompRack trashracks – General benefits

1 – Outstanding mechanical performance

As the CompRack fiber composite material is linear elastic all the way up to break, you get a trash rack that will recover its shape even if it has been temporary deformed locally by unexpected forces. This feature reduces the overall damages and in combination with a fully modular system, it makes it possible to replace individual parts of the trash rack in a very simple way.

Materialdata according to test SS-EN ISO14125:1998 made by Sicomp (www.sicomp.se).

Flexural strength, average ± standard deviation (MPa): 928 ± 45

Flexural modulus, average ± standard deviation (GPa): 47.6 ± 0.6

Elongation to break, average ± standard deviation (%): 1.99 ± 0.07

2 – Corrosion free = Maintenance free solution

This is a very important feature especially on fish-friendly trashracks when using narrow gaps between bars. All parts made of glass-fiber composite material or stainless steel, A4 quality.

– No need for surface treatment or other maintenance under normal conditions during the service life, >30 years, results in reduced maintenance costs.

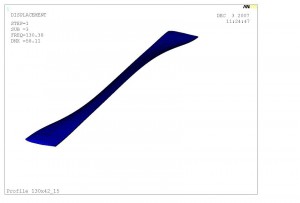

3 – Reduced head-loss, due to the optimized profile

The CompRack profile will significantly reduce the head-loss through the trash rack because of the optimized shape of the profile. The form-factor ~0,8 is only 1/3 compared to a flat steel-bar with the same width (form-factor ~ 2,42). This is especially important when the water-speed is increasing.

4 – Lightweight system

CompRack is a lightweight system, which simplifies installation and maintenance. ( weight approx. 25-30% of a comparable steel solution)

5 – Reducing marine growth

As well as by ice-problems the very fine surface roughness of Ra<1 μm is important to reduce the marine growth.

6 – Environmental friendly

Corrosion free – No need for sand-blasting or painting improves the environment.

Increased efficiency of renewable energy production has a positive environmental impact.

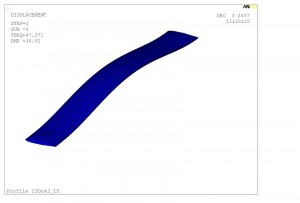

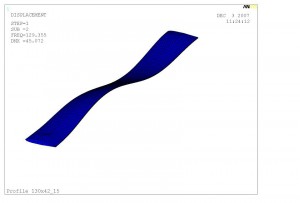

7 – Reduced risk of vibrations, due to an optimized profile.

The profile has been optimized to get a minimum of obstruction of the flow, which results in a low energy Karman-vortex shedding.

8 – Reducing ice problems

Reduced ice-problems gives higher availability and increased efficiency.

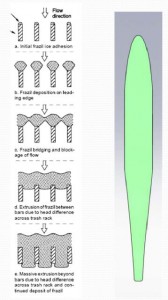

Fracile ice problems

The optimized profile of the CompRack bars gives a laminar flow through the trash rack. The reduced obstruction of the flow reduces the risk of ice build-up at the front edge of the bars which is the point were fracile ice starts to grow when these conditions occur.

The composite material also has a low thermal conductivity and in combination with a very fine surface roughness Ra<1 μm, the ice adhesion-forces are lower than to steel. If ice anyway would build up on the composite during extreme conditions, it is possible to take it away with a TRCM because of the lower adhesion forces between the ice/composite.

As a comparison cold formed steel bars has normally a surface roughness of 5-10 μm and hot formed 15-25 μm. The stated surface roughness of steel is the initial roughness, when corrosion has started the roughness increases fast and also the adhesion forces between ice/steel.

Picture (a)

Picture (b) (c)

Picture: (a) (b) (c)

a: CompRack trashrack,

b: Pattern of frazil ice accumulation on intake trash rack bars. Build-up starts at front surface.

c: CompRack , flow optimized profile shape with minimized front surface.

Floating ice.

The composite has excellent properties handling local impact-forces caused by floating ice. When the ice is stopped against the trash rack there is also a significantly lower risk that it freezes into the trash rack because of the low thermal conductivity of the composite. When the pressure between the ice and the composite profile is increased the melting temperature is decreased, which means that the trash rack bars will cut through the ice.

9 – Improved self-cleaning performance

Due to a very fine surface roughness Ra<1 μm, the friction forces are lower than to steel. This makes it also easier to achieve a better self cleaning performance of the trashrack, when using a reduced angle (<45 degrees to the horizon).

It is easier for the trash (leaves, grass etc.) to slide through the trashrack or upwards, towards the surface.

As a comparison cold formed steel bars has normally a surface roughness of 5-10 μm and hot formed 15-25 μm. The stated surface roughness of steel is the initial roughness, when corrosion has started the roughness increases fast and also the friction forces between trash/steel.

10 – Exchangeability

The CompRack system is fully modular with all the advantages that means.

The system is built around flow-optimized profiles that are tied together with spacer parts and rods, like a pre-stressed steel solution trash rack, but with the advantages using glass-fiber composite.

The trash rack sections are easy exchangeable if necessary, because of the reduced weight, only 1/3 compared to a steel solution.

When the TR-section is exchanged with a spare one, to reduce down time, it is also easy repairable because the profiles are linear elastic and will return to their original shape.

This makes it fast and easy to disassemble the trash rack, identify and replace profiles that are permanently damaged. All this can be done without heavy lifting-equipment available.

= Competitive lifecycle cost.

The combination of all these features gives an advantage when calculating the lifecycle cost.

Making an estimate of the valid cost benefits for each one of the above listed features helps you calculating the lifecycle cost.

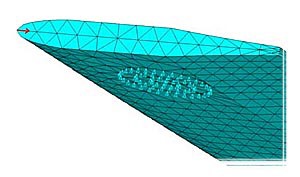

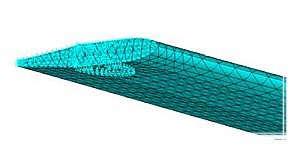

Picture: Cross section of a CompRack trashrack panel